Contact/Non-Contact Sensor Introduction

In the construction of industrial automation projects, Longzhong often needs to use some sensors to assist in the measurement, and there are many types of sensors, which need to be selected according to the environmental conditions of the construction site. Today, we Longzhong will come to introduce the types of sensors to you!

First of all, sensors are divided into "contact type" and "non-contact type".

A touch sensor, as its name implies, will touch the object to be measured during measurement. The touch sensor is often used in the production process of various industries. The most famous touch sensor is the limit switch.

Limit switch

A limit switch is an electromechanical device that has an actuator mechanically linked to a contact. If an object touches the actuator, it touches the contacts, opening or closing the electrical connection. Because the limit switch is sturdy, easy and safe, and its operation reliability is high, it is commonly used in many different environments and applications. In addition to detecting whether an object exists, it can also detect whether an object passes through a certain point, or whether it finally stops at a certain point.

●Advantages:

1. Compared with electronic switches (such as proximity switches), it is less affected by the electromagnetic interference of the application environment and causes malfunctions.

2. It has good temperature and humidity resistance, and can be better applied to some applications where electromagnetic interference, high temperature and high humidity are required to ensure the correct mechanical action.

●Disadvantages:

1. Mechanical life is limited.

2. The probability of limit switch wear and damage to the detection object is relatively high, and this method is not recommended for precision objects.

The non-contact sensor can detect whether there is a detection object approaching under the condition of non-contact detection of the object, and its principle is to convert the movement information or presence information of the detection object into electrical signals. There are electrostatic capacitance type, ultrasonic type, photoelectric type, magnetic induction type and other types.

Capacitance sensing

is a typical object/level/level detector. Capacitive sensors can not only detect metals, but also non-conductive objects. It can accurately detect the level of liquid and the level of bulk materials and particles through the container wall. When an object enters the electric field of the capacitor, the capacitance The sensor can change the capacitance as the detection object approaches, and detect the change of its capacitance value.

●Advantages:

1. Simple structure, good adaptability to harsh conditions such as ambient temperature, radiation and strong vibration.

2. Non-contact measurement and high sensitivity.

●Disadvantages:

1. High output impedance and poor load capacity.

2. The connection lines are more complicated.

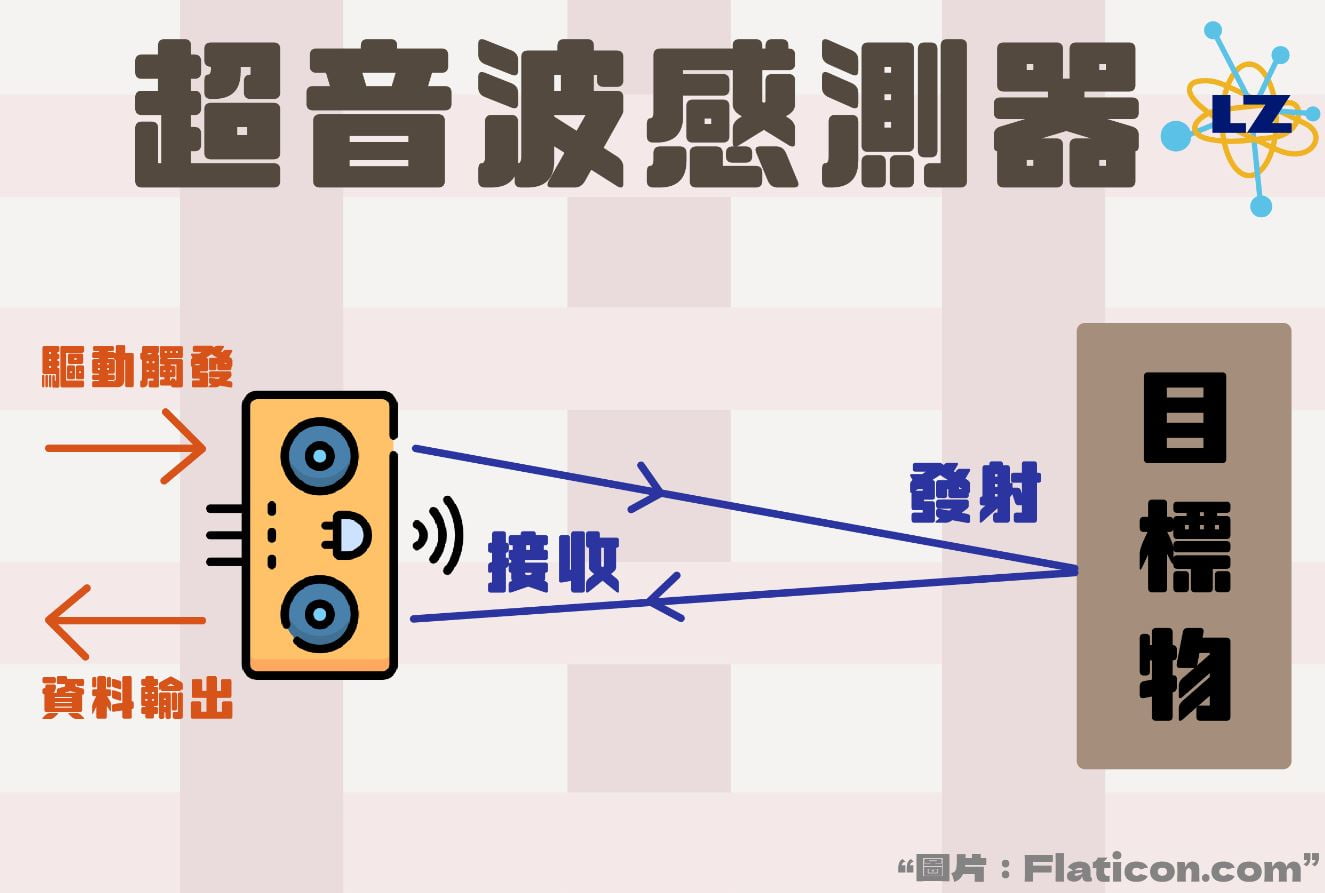

Ultrasonic Sensing

The way it works is similar to how bats use echolocation to find their prey in flight. The transmitter emits high-frequency sound waves (ultrasonic waves) to the object to be measured. Calculate the correlation between the time it takes to receive ultrasonic waves and the speed of sound to confirm the existence of the measured object and obtain the distance between the sensor and the measured object.

●Advantages:

1. The color of the measured object will not affect the measurement accuracy, and transparent or translucent materials such as glass and water will not negatively affect the performance.

2. Provides excellent flexibility for long-distance object detection and distance measurement, with typical values ranging from a few centimeters to the most distant meters.

3. Easily available and composed of relatively inexpensive components.

●Disadvantages:

1. Environmental conditions (eg temperature, humidity) will affect the accuracy and stability of distance measurement.

2. It can only be used to provide distance measurement or object detection. It cannot specify the location of the object, or provide information on the shape or color of the object.

3. Sound requires a transmission medium, so ultrasonic sensors cannot be used in vacuum applications.

Photoelectric sensing

The sensing principle is to convert the input current into an optical signal on the transmitter, and convert it into a current change through the change of light intensity between the transmitting and receiving ends. detection for the purpose of detection. Since the output circuit and the input circuit of the photoelectric switch are electrically isolated (ie, electrically insulated), they can be used in many occasions.

●Advantages:

1. It can realize non-contact detection conditions, with high precision, fast response and many measurable parameters.

2. The structure of the sensor is simple and the form is flexible and diverse.

3. Can realize color discrimination.

●Disadvantages:

1. The detection distance is short.

2. Susceptible to disturbing light sources.

Magnetic Sensing - Reed Switch

Reed switches are the most common type of magnetic sensor. When a magnetic field with the direction of the magnetic field line perpendicular to the direction of the current passing through the iron bar is applied to a thin iron bar, the resistance in the iron bar will change. The reed switch determines the magnetic field strength by measuring the resistance change.

●Advantages:

1. Can be used to detect a variety of physical measurements, such as: position sensing, speed and direction of motion sensing.

2. Robust, highly repeatable and almost maintenance free.

3. Not affected by vibration, dust and water, and low cost.

●Disadvantages:

1. External magnetic fields may affect the accuracy of measurements.

2. Not heat resistant, high temperature may affect sensitivity.

3. The measurement distance is limited and should not be too far.

After reading the whole article, you should be able to understand that no sensor is omnipotent, so Longzhong will choose the appropriate sensor according to the site environmental conditions when planning and designing. Without this expertise, it may result in poor engineering results and, in severe cases, even affect the entire process.

If you have any requirements for the control of the instrument and electrical system,

Longzhong providesTechnical Advisory Services | Tel: 06-243-7822