Ultrasonic Flowmeter

Today we are going to introduce──Ultrasonic flowmeter

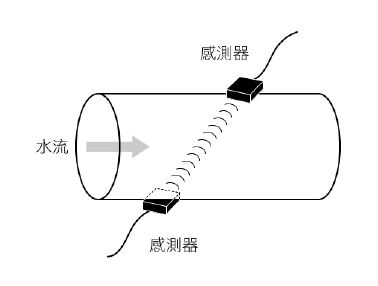

Two probes (sensors) are installed outside the pipe wall. When the ultrasonic waves are transmitted between the probes on both sides, the time difference proportional to the flow rate is generated in the two directions of the forward flow and the reverse flow, and the flow rate is calculated based on this. Ultrasonic waves are alternately received/transmitted after traversing the fluid in the pipeline at an oblique angle. When the ultrasonic waves advancing through the water are in the opposite direction to the water flow, the propagation speed will slow down; The speed will be faster.

Advantage:

・No pressure loss

・There is a type that can be detected from outside the pipeline

Shortcoming:

・Requires a longer length of straight pipe

・Liquids containing larger solids will cause malfunctions

・Cannot test when there are many bubbles

Reasons for flowmeter failure:

1.Scale

2.Sludge

3.Rust

4.Sticky

5.Mud

6.Bubble

7.Non-uniform velocity distribution

8.Ripple

9.Pipeline Vibration

Recommendations for installing the flowmeter:

1.Install enough straight pipe sections

If possible, be sure to install a straight pipe section equal to 5 times the inner diameter upstream of the flow meter, which can eliminate non-uniform flow rate and convert to uniform flow rate.

2.Make the fluid flow from the lower section to the upper section

A full accumulation state is generated. When the flow channel is in the state of full volume, the measurement effect of the flow sensor is the best.

3.Installed in the low section of the pipeline (to prevent air bubbles from flowing into the fluid)

4.Install bypass (improves maintainability)

source:KEYENCE

Automatic control design planner ─ Longzhong Enterprise

Technical Advisory Services | Tel: 06-243-7822

- PREVImpeller Flowmeter

- NEXTFloat Flowmeter