Air compressor remote system data automatic integration and graphic control

Today I want to share a case with you. The owner needs a system that can remotely control the status of the air compressor, and hopes to integrate the parameter data of the air compressor. Originally, the owner's factory used manual data copying. When the machine was abnormal, the personnel could not judge the cause of the abnormality. Not only the urgency of the time pressure in the operation, but also the possibility of errors in the handover of personnel.

Later, I found us, Longzhong, and asked us to help automate the process of recording data of the air compressor, and hoped that in the planning of the improvement project, it would be convenient for the operator to control.

Looking for Longzhong to plan the automatic integration of remote system data, you can remotely master your mechanical status and record all instrument data!

According to the needs of the owner, Longzhong planning and operation projects are divided into hardware/software:

●Hardware: On-site piping and wiring configuration, assembly data communication panel

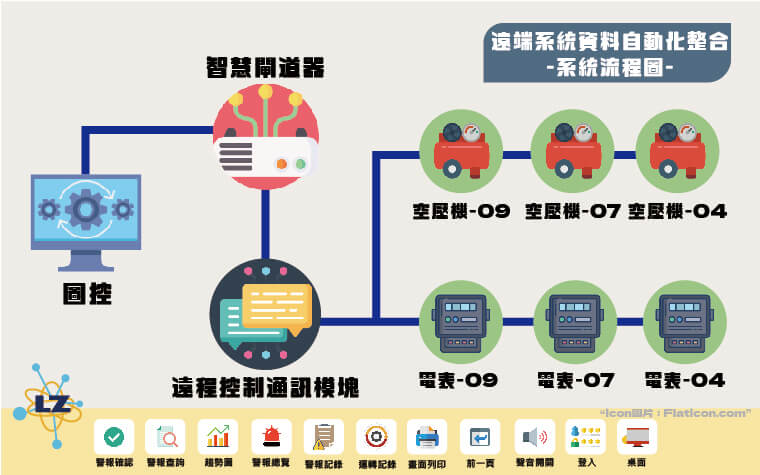

●Software: After converting the air compressor signal, it is connected with the communication interface together with the electric meter signal, and then transmitted to the graphic control panel for display.

Because of the need to master the operation data of the air compressor, the remote communication module must be used to capture the internal signal of the air compressor. Through the CGW communication interface, the air compressor signal and the electricity meter information data are sent back to the graphic controller. After presenting the data on the graphic control screen, the case was completed after several times of communication software tests on the information link, and it was confirmed that there was no problem.

The automatic integration of remote system data and the realization of invisible values can bring these benefits to your factory:

✦ Save Human Resource Costs

✦ Significantly shorten the time and process of data collection operations

✦ It can judge the abnormal cause of machine parameters according to the display of various parameters

✦ When abnormality occurs, it can be detected in time, and more processing time can be obtained

Have any system information integration and graphic control requirements

Longzhong provides Technical Advisory Services | Tel: 06-243-7822