Map control alarm monitoring of adsorption dryer tank tank differential pressure gauge project

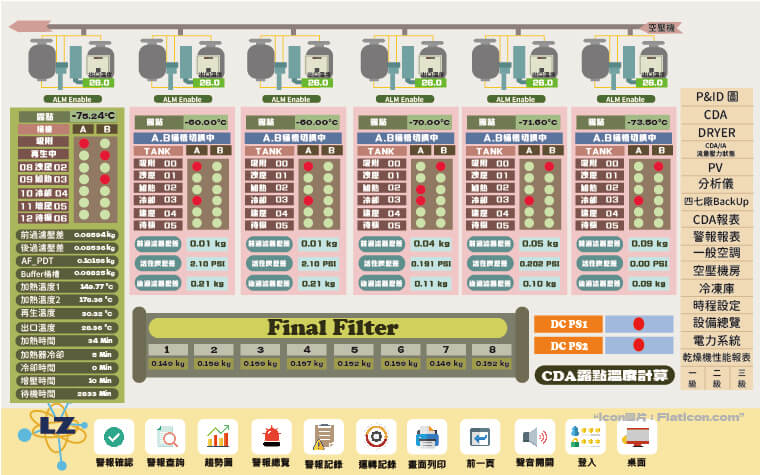

The adsorption dryer barrel tank differential pressure gauge project for graphic control alarm monitoring is to use PLC program design to automatically control the adsorption dryer tank tank differential pressure gauge measurement, and return the measured pressure difference data of the tank tank to the graphic control interface for monitoring. And when the data is in a state, the system will automatically issue a graphic alarm.

Today I want to share with you a customer of Longzhong, a high-tech panel manufacturing company, who uses high-pressure drying air in the process. Therefore, an air compressor is used to generate high-pressure air. The high-pressure air produced by the air compressor contains a lot of moisture, so the air produced by the air compressor needs to be treated with a dryer before it can be used.

Difficulties encountered by customers

The original filter differential pressure gauge on the customer's dryer is installed at both ends of the inlet and outlet pipelines of the filter to monitor the pressure drop of the pipeline to ensure the performance of the filter, which helps to maintain the compressed air quality at a certain level permanently.

However, if customers want to switch to tank differential pressure gauges, they can then observe and compare the pressure loss and consumption of different adsorption materials used in the tank, so that in the future, the adsorption material with the lowest consumption rate can be selected to save production costs. The customer also hopes that Longzhong can help automate the system: when the adsorption material in the tank is seriously depleted, a warning can be issued through the graphic control alarm system to remind the factory staff.

This demand requires the redesign of the circuit and the addition of monitoring piping, so the owner asked us, Longzhong, to assist in handling the graphic control alarm monitoring project of the differential pressure gauge in the tank of the adsorption dryer.

Longzhong offers a solution

According to the layout of the factory, Longzhong's engineers tailor-made the monitoring system planning line piping design for customers. The programmable logic controller part is Siemens S7-400, which is one of the medium and large PLC models frequently used by Siemens. It is particularly worth mentioning that S7-400 is a multi-connected system (also known as: redundant), that is, when a single CPU fails or other conditions, the system does not need to stop, and only needs to replace the broken part to go online directly. . Also because of this feature, it is often used in the system configuration of medium and large factories, especially chain reaction systems.

The engineers use the S7-400 PLC logic controller to connect the differential pressure signal in the tank, which can stably collect the on-site differential pressure data and send it back to the graphic control screen, which is convenient for monitoring and understanding the situation at any time, and the management personnel can also You can set the alarm value by yourself, and when the data exceeds the set standard, a graphic alarm will be issued. Knowing that the adsorption material in the tank of the adsorption dryer is blocked early can make the personnel vigilant and arrange replacement as soon as possible. Otherwise, when the pressure loss is too large, the CDA pressure will drop, and the air compressor will have to do more work to reach the end pressure under normal conditions. . Replacing the state of the adsorbent in advance can prevent the additional increase in electricity costs.

From piping design and wiring to graphic control interface installation, sensor sensing signal point connection, PLC program design... etc., customers do not need to hire multiple contractors, and do not need to coordinate with various manufacturers. We can provide all-in-one package service when looking for Longzhong, which is one of the reasons why customers feel at ease looking for Longzhong.

Information integration is our specialty at Longzhong! Through the professional Siemens PLC programming technology, you can integrate the required systems in your factory area and automate the equipment, so that you can not only facilitate management and improve the operation efficiency in the factory area, but also save equipment production/operating costs.

Have any graphic alarm system needs

Longzhong providesTechnical Advisory Services | Tel: 06-243-7822