Siemens PLC diagnostic module function program writing project

PLC programmable logic controllers are often used in industrial operations, and it is not unavoidable to encounter PLC failures but do not know where the problem is. Longzhong can assist the business to review the PLC and system construction environment, and whether it can write diagnostic functions to support hardware modules, which is also our specialty at Longzhong. Through the automatic debugging of the PLC program, it can clearly point out which module has a problem for you, reducing a lot of debugging and testing time.

Difficulties encountered by customers

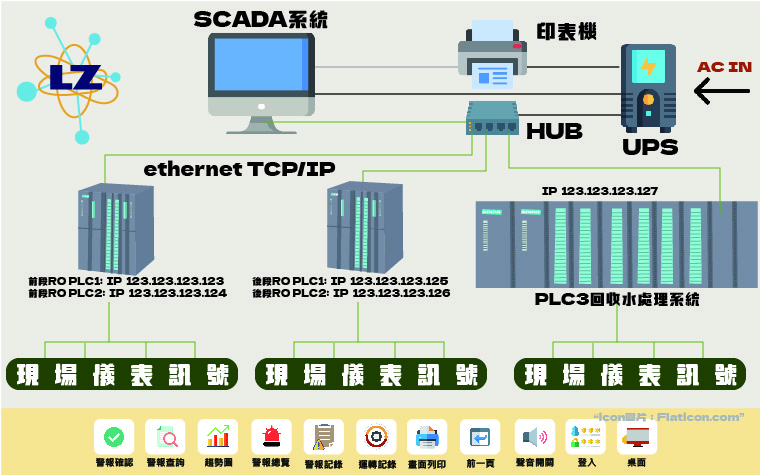

The pure water system in the owner's factory area uses Siemens PLC, and the Siemens basic module has no DI/DO diagnostic function and no light display. Therefore, whenever there is a problem with the PLC, the factory staff can only see some errors displayed on the PLC on the graphic controller, and have no way of knowing which module has the problem. They can only wait for professional engineers to come to check and repair, resulting in a lot of wasted waiting. Time and production line downtime costs.

Longzhong solution

Through Longzhong's professional graphic control programming technology, he wrote the Siemens PLC diagnostic module function program for the owner. The program is divided into three stages of diagnostic program processing:

‧ Phase 1: Confirm whether the communication of each substation under the PLC Profibus is normal, diagnose whether the CPU light is normal

‧ The second stage: IM153-2 bottom IO signal module is abnormal diagnosis ( DI, DO, AI, AO )

‧ Phase 3: Advanced diagnosis of AI and AO modules

Siemens S7-400 module diagnosis system designed according to Longzhong can effectively save you the time of checking and repairing the abnormal range.

Have any PLC program requirements

Longzhong provides Technical Advisory Services | Tel: 06-243-7822