CASE Graphic Control Systems

Graphic Control Systems

Chemical shower and eyewash station door open alarm automatic signal feedback

Chemicals have complex compositions and diverse types, and they come with certain risks. Generally, factories that use chemicals are equipped with "body and eye wash stations". We at Longzhong can help add functions such as door opening alarms, automatic signal transmission back to SCADA for display and notification to the central control room, and post-accident tracking and recording functions to serve as a basis for reporting upwards.

Graphic Control Systems

Modification of the InTouch program of the factory graphics control system

The owner's exhaust system graphic control program has some bugs and often misjudges communication abnormalities, causing the main and backup machines to constantly switch back and forth and unable to operate normally. After Engineer Longzhong modified the graphic control program and added comprehensive logic conditions, the factory exhaust system ran smoothly, and the status of the PLC could be clearly seen on the InTouch graphic control.

Graphic Control Systems

construction joint water leakage map control detection

To find the leak point, the factory staff have to venture into the interlayer of expansion joints in the building where there is no light at all, which is time-consuming. Longzhong assisted in optimizing the process of checking and repairing water leaks, and reversed the link map control to receive an alarm. First, he knew that there was a water leak in the expansion joint and where the leak could be located.

Graphic Control Systems

Map control alarm monitoring of adsorption dryer tank tank differential pressure gauge project

Use the PLC program to automatically control the measurement of the differential pressure gauge in the tank of the adsorption dryer, and send back the measured pressure difference data of the tank to the graphic control interface for monitoring. Comprehensive control of production expenditure costs.

Graphic Control Systems

Storage tank diesel leakage sensing alarm project

Longzhong designed a storage tank diesel leakage sensing alarm project for customers. Even non-conductive liquids such as oil or organic solutions can receive the occurrence of leakage through PLC and control subsequent graphic alarm functions. . This allows owners to understand the situation more quickly and conduct timely repairs to reduce the chance of damage expansion.

Graphic Control Systems

Air compressor remote system data automatic integration and graphic control

Manual data copying is not only time-consuming, but may also contain errors. Longzhong plans to automate the integration of remote system data. Through the graphic control screen, factory staff can remotely control the status of your machinery, automatically record all instrument data, and integrate remotely!

Graphic Control Systems

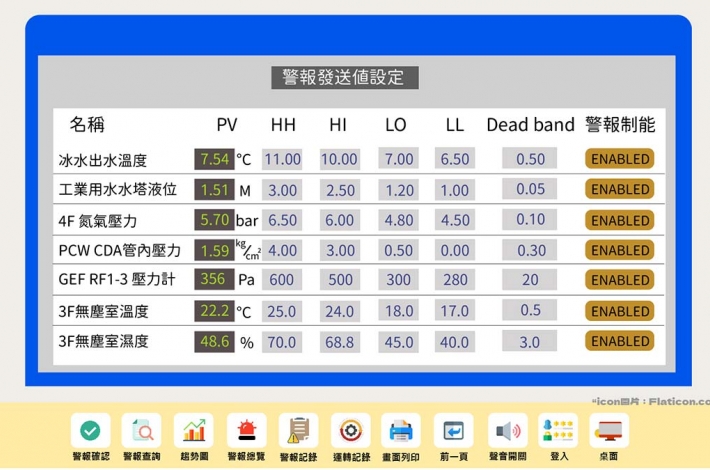

Factory equipment abnormal mail alarm system

The factory has various pipeline pressure values, water tower liquid levels, and dust-free room temperature and humidity monitoring data that need to be monitored. Longzhong integrates system information and sets up automatic email alert notifications for customers.

Graphic Control Systems

iFIX data control clean room AHU

iFIX provides process visualization, data collection and data monitoring of production operations, enabling rapid response to production events. Through iFIX, administrators can not only clearly monitor/control the AHU air-conditioning box system of the clean room, but also set the PID value of the windmill inverter by themselves, which can be set manually or automatically output control during operation, providing user-friendly management. choose.

Graphic Control Systems

Factory machinery and equipment utilization rate and situation room kanban

What is the utilization rate - it is a ratio that measures the usage status of the equipment from the perspective of the equipment. The simple calculation formula for the utilization rate is (operation time/load time)*100%, which is the percentage of time that the equipment is actually running

Graphic Control Systems

Clean room inspection PLC automatic leakage detection detection graphic control alarm

Longzhong has many years of experience in assisting in automatic liquid leakage inspection of clean rooms. Through the PLC program graphic control alarm design, it can automate the clean room leakage detection process and issue graphic control alarm notifications when there is a situation, helping owners to effectively reduce costs. Labor costs.

Graphic Control Systems

Air compressor system integration project

Air compressor (also known as air compressor) refers to a machine used to compress air to increase gas pressure. Almost all walks of life can see its existence. If air compressor equipment is used in an industrial system combination, integrating information through graphic control will make the overall work process much more convenient.