#Follow Longzhong across the sea to Beijing: Remote plc update control program system engineering-THE END

ex love story summary:

Click me to see the story-1: Overseas emergency engineering services

Click me to see the story-2: PLC vacuum system control overseas engineering technical support

Completing this arduous task of PLC control and integration of vacuum equipment across the sea is not the end for Longzhong, but the starting point for ushering in another level of automation technology: Remote remote PLC update control program system engineering.

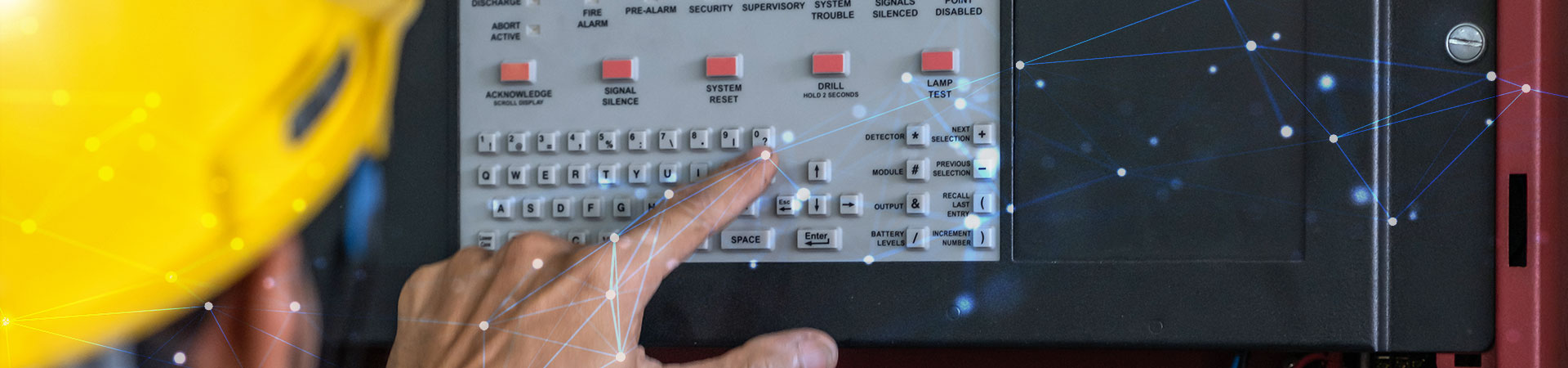

When the maintenance personnel cannot rush to the scene to deal with it in the first time, Longzhong has the remote PLC program control and modification technology, and the PLC remote programming can be connected to the Internet to carry out equipment system engineering debugging, modification and update.

Longzhong and his team completed the control and integration of vacuum equipment in Beijing, and handed over the operation and management of vacuum pumps, vacuum valves, and graphic control interfaces to local managers before flying back to Taiwan.

One day after returning to Taiwan, I suddenly received a call from the owner in Beijing. The owner reported that some parts of the communication link between the vacuum cryopump equipment and the PLC programmable logic controller would like to be modified, and some partial adjustments should be made to the conditions of the automatic control program. I would like to ask Longzhong if he is free to fly across the sea again in the near future Go to Beijing to assist in processing.

PLC program repair and engineering change program services, especially for overseas system engineering equipment, are unable to rush to the site to solve problems for customers in time. The biggest limitation is the problem of "immediacy" and "distance". The suspension of overseas equipment system engineering naturally also means that the equipment is idle and ineffective, and the cost will increase accordingly. Originally requesting cross-sea support is a considerable cost to the owner, and the waiting time added will actually have a considerable impact on the overall enterprise, and the resulting losses are difficult to estimate.

Longzhong understands these indescribable pains.

In order to avoid such immediate emergencies, Longzhong actually prepared the record before returning to Taiwan!

When Longzhong engineers were still in Beijing, they installed the remote control software program in the client's computer in advance. In response to the modification of the PLC program requirements, Longzhong does not need to fly overseas again, and can operate in Tainan and customers as far away as Beijing through computer and telephone connections at the same time. After the remote control software has passed the verification, it will use the remote connection method to control across the sea, monitor the vacuum equipment system in real time, modify the remote PLC program according to the customer's needs, update the remote PLC program, and eliminate the logic problems of the automation program... ...and so on, after the modification, it can be connected and accepted immediately. If there is any logic control problem, you can make real-time PLC program design adjustments to realize remote monitoring and PLC update, maintenance, debugging and modification!

Since we only had cooperation experience in Beijing not long ago, the communication between the two parties was very smooth when we were still familiar with this case. We modified the communication link between the vacuum cryopump equipment and the PLC programmable logic controller required by the customer. , and also made local adjustments to the conditions of the automatic control program according to the customer's planning requirements. Longzhong breaks the distance and real-time limitations of cross-sea automation control services, and saves customers the waiting time and money costs that were originally planned for Longzhong to fly to Beijing for support. Remote control can also fulfill the customer's PLC update system engineering requirements, find out the equipment control logic problems and eliminate them.

Friends who have any remote PLC update maintenance, remote PLC troubleshooting

Longzhong providesTechnical Advisory Services | Tel: 06-243-7822