Stripping Tower Automated Ammonia Wastewater Treatment System

Operating principle of stripping tower:

The stripping tower uses the mass transfer effect to operate the wastewater containing ammonia nitrogen under alkaline conditions, pull the pH value to about 11, and separate the ammonia from the liquid phase by contacting with the air flow, and remove the ammonia Comes out as ammonia gas.

The stripping tower is responsible for extracting the ammonia gas, which needs to be performed together with the absorption tower. After the gaseous ammonia is separated from the stripping tower, the absorption tower is used to combine it with sulfuric acid to form ammonium sulfate, and then adopt other systems to adjust the pH value for treatment and recovery. The stripper is used to remove the ammonia in the wastewater, which can not only share the load of the wastewater treatment system, but also reduce the impact on the environment.

How to deal with the ammonia absorbed by the absorption tower?

When the absorption tower is in operation, the process of absorbing ammonia to produce ammonium sulfate is very cumbersome, and it is usually necessary to arrange personnel to operate and control it in batches.

Longzhong can assist customers to automate the ammonia wastewater treatment system.

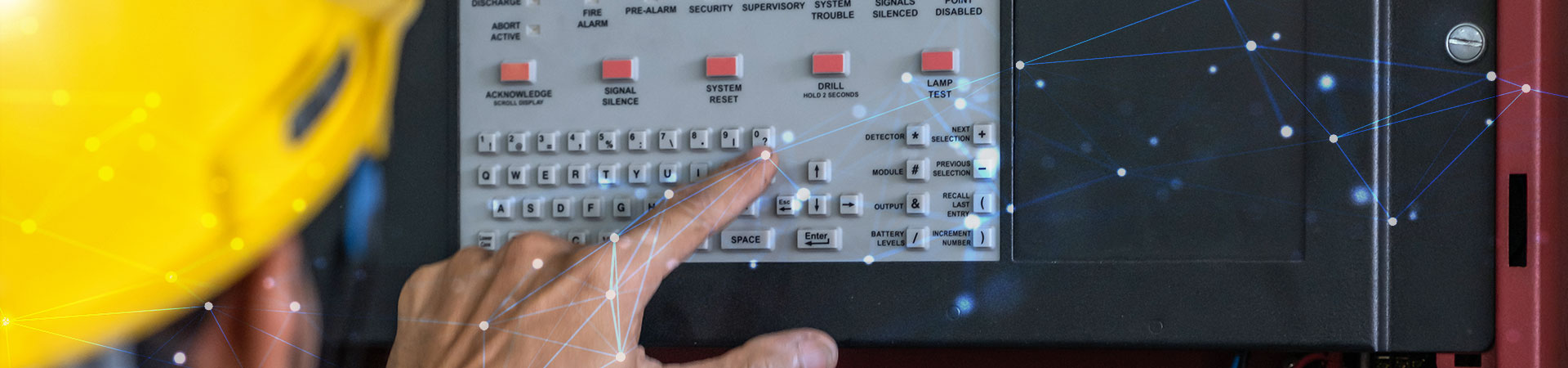

The PLC logic design of automatic control is used to control the overall equipment of the gas stripping tower and the absorption tower of the client, and then the PLC is combined with the man-machine interface to operate, so that the whole ammonia wastewater treatment system can absorb ammonia in batches and achieve automatic operation.

Customers no longer need to arrange additional human monitoring in this step, which can effectively save labor costs for you. Longzhong specializes in the integrated monitoring of the waste water treatment system of the stripping tower. Through the machine equipment data to adjust the flow control and equipment status monitoring and control, the fault display reminder can be displayed, and the on-site operation of the process can be understood to improve reliability, stability and safety.

The Necessity of Ammonia Control for Water Environment

Ammonia is a colorless gas. The most frightening thing is that when the indoor ammonia concentration reaches a certain level, there will be a pungent smell.

● The nitrification process will consume dissolved oxygen in water, resulting in deterioration of water quality

● Eutrophication in closed water bodies will allow microorganisms and algae to multiply, consume dissolved air in water and affect the ecosystem

● Toxic to aquatic organisms in high concentrations

● Causes unpleasant (smelly) odor and is harmful to human health

The raw materials and chemicals used in the manufacturing of semiconductors, wafers, and optoelectronic panels in the current high-tech industry are becoming more and more complex, and the problem of wastewater discharge is unavoidable in the process. Since the stripper is usually used for cleaning and removing particulate pollutants on the surface of the wafer in semiconductor-related industries, The high concentration of ammonia nitrogen in the discharged wastewater will cause acute ammonia poisoning to aquatic organisms and cause water pollution.

Ammonia gas will not only cause harm to the environment, but also cause great harm to the human body. Therefore, when planning and constructing factories in many high-tech industries such as semiconductors, wafers, and photovoltaic panel manufacturing, the first consideration is the stripping tower equipment. of additions.

Longzhong Enterprise has built airless stripping tower equipment and is proficient in PLC logic control equipment.

We can assist the stripping tower equipment in your plant to establish an automated ammonia wastewater treatment system. Automation control engineering such as integration of other systems and human-machine interface is also our strong point.

Have any requirements related to PLC control stripping tower equipment and system integration

Longzhong provides Technical Advisory Services | Tel: 06-243-7822