PLC control signal return of factory pure water system

Longzhong plans the PLC control factory pure water system signal return project, which can make the monitoring of pure water quality in the factory area more timely and convenient, and it is also easier to maintain and repair.

Pure water systems often need to be used with many sensors, such as: pressure gauges, tank level gauges, resistance gauges...etc., these values need to be monitored and controlled. As the demand for water automation systems grows, pure water systems no longer only require monitoring, but require more intelligent judgment and control.

Difficulties encountered by customers

The remote I/O module used in the original pure water system, although the construction speed is fast and the construction cost is relatively low, but it can only watch the data and cannot control it. If there is an abnormality in the sensor in the factory, it must be diagnosed by a third-party computer, and it is easy to find and repair the situation.

The owner hopes that Longzhong can assist in improving the signal return, and hopes to achieve automatic control of sluice valves, filter water quality... and other related water system control requirements.

Longzhong offers a solution

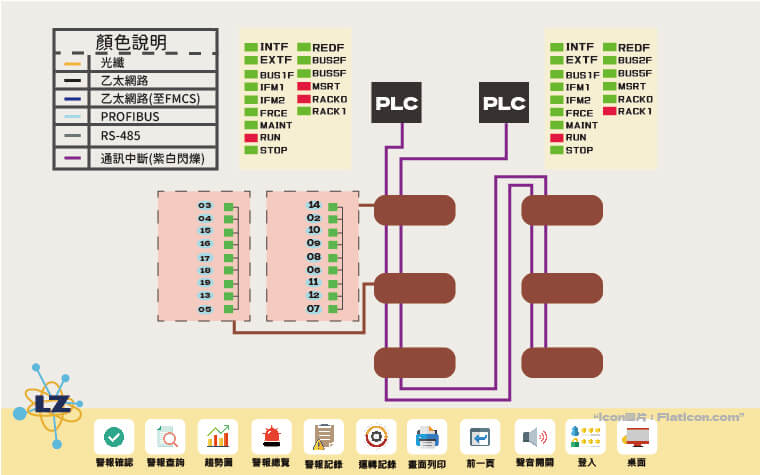

Engineer Longzhong integrated the signals originally controlled by remote I/O modules into the Siemens S7-300 PLC used by the original owner for signal system control, so that monitoring and control can be achieved.

When the sensor enters the AI module, there is an independent circuit fuse. Even if there is an abnormality in the on-site sensor, it will only cause the fuse of the sensor to blow, and will not directly affect the entire I/O module of the PLC. operate. And the use of PLC control system is relatively convenient for future maintenance and repair. It only needs to eliminate a single sensor abnormality, and it is also relatively easy to replace. After the installation, no complicated software settings are required.

Through S7-300 PLC control, the pure water system can no longer simply monitor the data, but can perform control modification operations after direct calculation. It not only makes it convenient for you to manage the system, but also greatly improves the efficiency of factory operations.

Have any plant water system control needs

Longzhong provides Technical Advisory Services | Tel: 06-243-7822